Rotomoulding makes it possible to produce many parts for the most diverse sectors, such as agriculture, industry, furniture, toys, civil construction. As a result, products are manufactured with a more complex and better-finished design, with a wide variety of colors and textures.

This process allows you to manufacture an unlimited range of products, from small and sophisticated objects up to large and complex products, with a single opening and without joints. The product range goes from micro-molding PVC earpieces to large polyethylene tanks. Any other process could not produce some of these items.

In this article, we will introduce you to some rotational molded products and explain how rotational molding machines work.

Some sectors that use rotational molding

Construction

Nowadays, the use of plastic in many construction solutions is very common, such as roofs and windows, slabs and coatings made with EPS, hydraulic systems, ventilation, water tanks, and sanitation systems.

Water tanks

Wheelbarrows

Toys

Rotomolded toys, such as balls, dolls, strollers, bicycles, and playgrounds, stand out for their beauty and resistance.

Trolleys

Tricycles

Playground

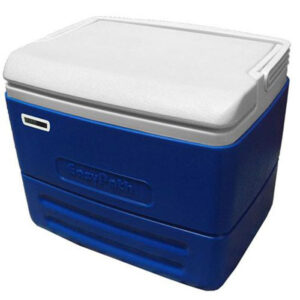

Boxes and packaging

Rotomoulding also uses products for packaging and transport in industry and commerce, such as pallets, boxes, pallets, dumpsters, organizers, containers, and many other products.

Plastic box

Coolers

Dumpsters

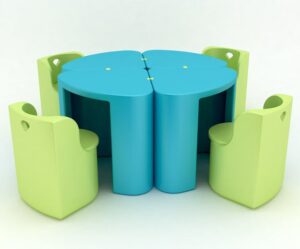

Furniture

It is possible to produce furniture of different sizes, colors, and textures in the furniture sector, such as benches, chairs, tables, armchairs, loungers, and lamps.

Tables and chairs

Park bench

Agriculture

Water and fuel tanks, sprayers, nozzles, fairings, fenders, cisterns, boxes, flowerpots, fertilizers, seeders, tents for greenhouses.

Tanks

Sprayers

Fertilizers

Nozzles and accessories

See how rotomoulding machines work

Rotomoulding machines have two basic configurations, bi-axial machines and Rock and Roll machines (swing and twist).

The most common and versatile machines are the “Carrossel” model, with a bi-axial concept, with a configuration ranging from three up to five arms with and up to six workstations, automatic indexing in each station, according to the molding cycle programmed. This type of machine is more suitable for production in series.

For varied parts production, the most recommended machine model, that also use a bi-axial concept, and is configured with linear cars is called Shuttle Machine.

After all this reading, we were able to get an idea of how rotomoulding provides a thousand possibilities. But if you are still not sure about this or want to see it further, take a look at our RotoIdeas content here..

If you are interested in knowing more about rotomoulding, have any questions, or want help getting your ideas off the ground, get in touch with us: