The rotomolding process is versatile, allowing several applications. In addition, it is much simpler and more economical than other plastic transformation processes, which also involve the transformation of thermoplastics.

The production of small rotomolded parts is already a consolidated reality in the plastic market, offering precision and a high standard of finishing to the products.

With this process and the possibility of creating products that other transformations would not be able to perform, it is possible to meet the specific demands of various segments such as industry, agriculture, civil construction, toys, furniture, etc.

That's why we've listed 6 advantages of producing small rotational molded parts, especially when manufactured on the market's first of a rotational molding machine: the Rotoline Sphere Oven SO 1.60.

Check out the advantages of producing small rotomolded parts

1. The parts are highly resistant to impacts and weather exposure, especially as they do not need to be spliced or welded.

2. The fact that they suffer low residual stress and do not contain seams, makes cleaning easier.

3. It is possible to optimize the production of parts and reduce costs, using different types of molds in the same rotational molding machine.

4. They allow versatility in production and application in several segments that sell or use small rotational molded parts.

5. The rotational molding process makes great use of raw materials, with low residual stresses and, consequently, generates more benefits with lower investments.

6. Rotational molding produces hollow plastic parts, a characteristic that guarantees products’ lightness. They are ideal for those who need to carry them or handle them frequently.

Sphere Oven SO 1.60 in the production of small rotomolded parts

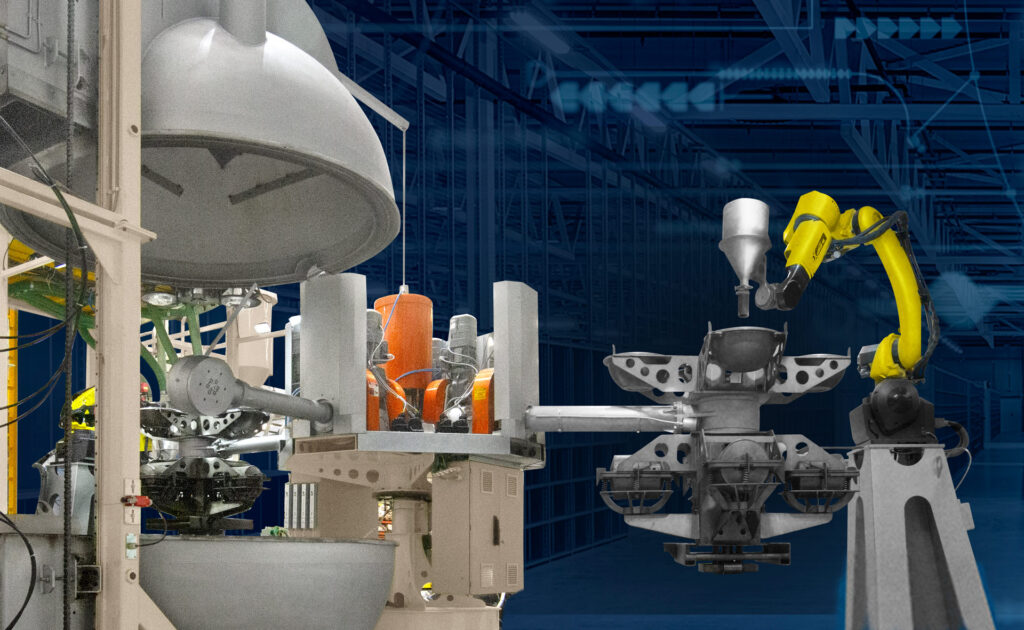

The Sphere Oven SO 1.60 is the first spherical oven machine on the rotational molding market.

With an innovative profile, the SO 1.60 offers high performance in the production of small rotomolded parts, especially due to the fact that it is automated.

The SO 1.60 has an automatic raw material weighing system and a robot arm capable of depositing precise amounts of polymers into the mold.

In addition, its design is another factor that makes it ideal for the use of small size molds.

This was our article about the advantages of producing small rotomolded parts with the Sphere Oven SO 1.60. Learn more about this machine that can revolutionize your industry by clicking the button below: