Machines operating in more than 20 countries on 5 continents.

In recent years, Rotoline has developed more than machines and equipment for Rotomolding, attentive to the needs of its customer, combined with the constant investment in innovation and cutting-edge technology, Rotoline is offering to the worldwide market solutions that meet the most diverse realities of each rotational molder.

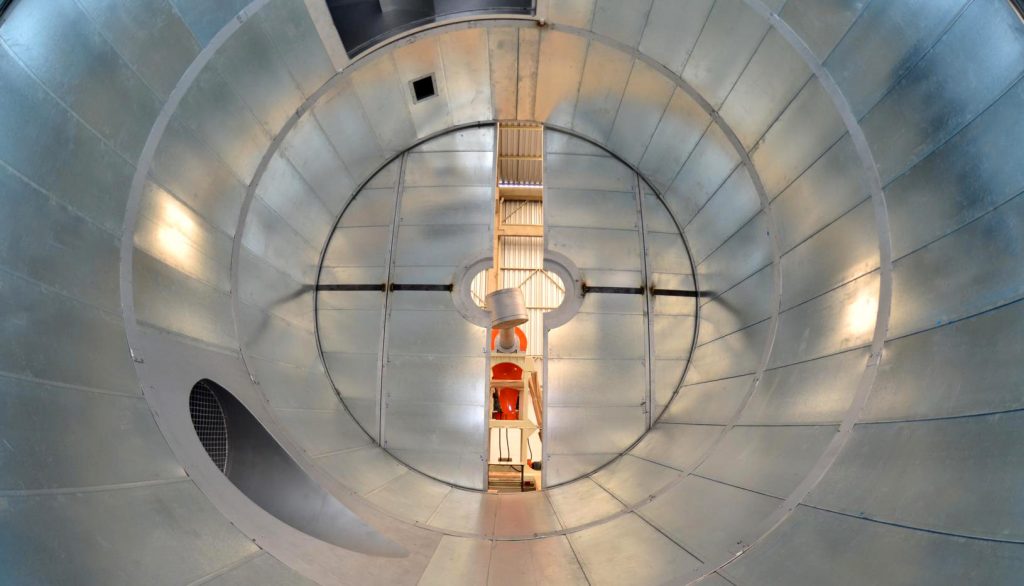

High efficiency oven: Better Distribution and Economy of Energy and Gas

A Rotoline pioneered the manufacture of machines with cylindrical oven, which provides a homogeneous airflow in all areas of the oven avoiding “dead spots”. The reverse flow also offers a considerable improvement in the distribution of heat inside the oven. All the structure of the oven, doors and ducts is protected by a special insulation system. The fit between the panels follows a pattern specially designed to ensure minimum heat loss and allow expansion. These details are directly linked to the gas consumption economy.

The heating system of Rotoline machines works with a high efficiency gas burner. The machine is supplied with a burner ready to operate with two different types of fuel gas, NG (Natural Gas) and LPG (Liquefied Petroleum Gas). The burner is monitored by an advanced fail-safe interlocking hardware to meet different safety standards. The oven temperature is regulated by a PID temperature controller fully integrated with the machine system. Rotoline machines work with a modulating burner, which allows temperature control resulting in energy and gas consumption savings..

Fully Controlled Process, allowing Repeatability and Traceability

The Machines PLC (Programmable Logic Controller) is loaded with a software management control system, which gathers information from multiple sensors such as temperature and pressure, installed in various parts of the machine, doing all the interlock and control functions of machine operation and providing a specific and concise input to the gas burner controller.

In the Machine Computer runs the supervisory software, continuously communicating with the PLC, and integrates automatic control parameters such as: Temperature, oven time, cooling time and arm/plate rotation. Using this interface the operator can make modifications to the program, monitor the process and obtain status reports and production info. This allows a full interaction with the machine and the process. All the interactions required to process a wide variety of products can be made using this package.

Start of Production in Less Time and Agility in Technical Assistance

With agile assembly and start up of the equipment, it becomes possible to start production in less time. The same agility applies to the technical assistance service, which is available in 3 languages. All Rotoline Machines have a Remote Connection Program, which is used to provide fast and efficient technical assistance. All machines sold have an Identity ID – Electronic and Physics File with all records from the beginning of its production – Purchase orders, drawings, electrical project, shipment and start up pictures. All this information helps Rotoline Team to offer an excellent after sales service.