Plastic Rotational Molding: Practical Guide

A rotomoldagem de plástico é uma das técnicas mais importantes para o desenvolvimento de produtos neste material. Se você está procurando um guia prático para entender e obter os melhores resultados

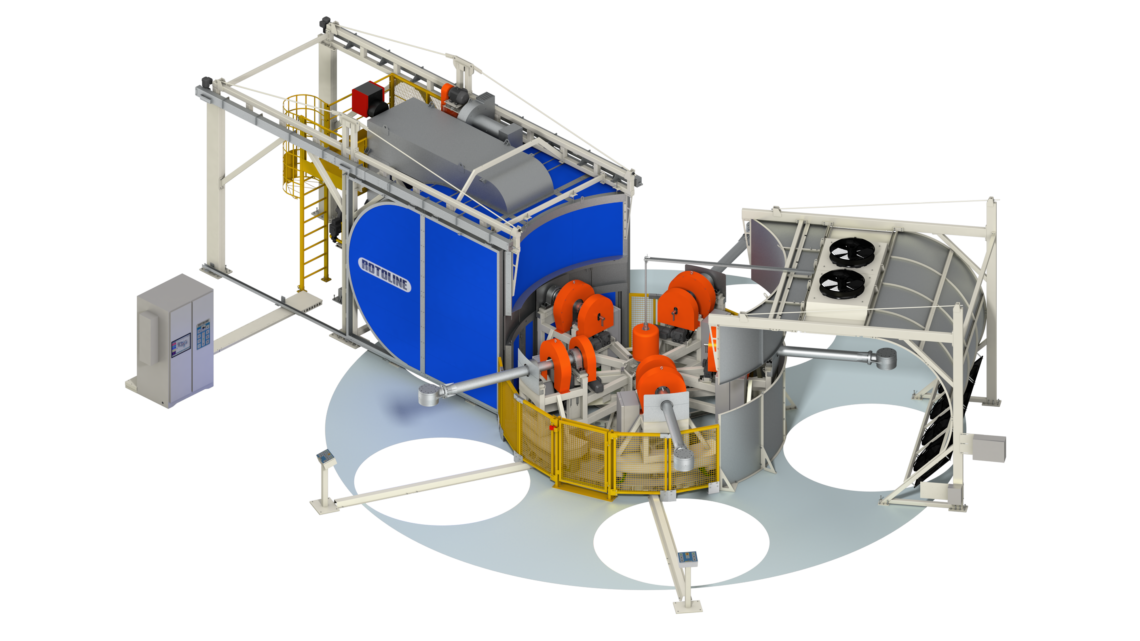

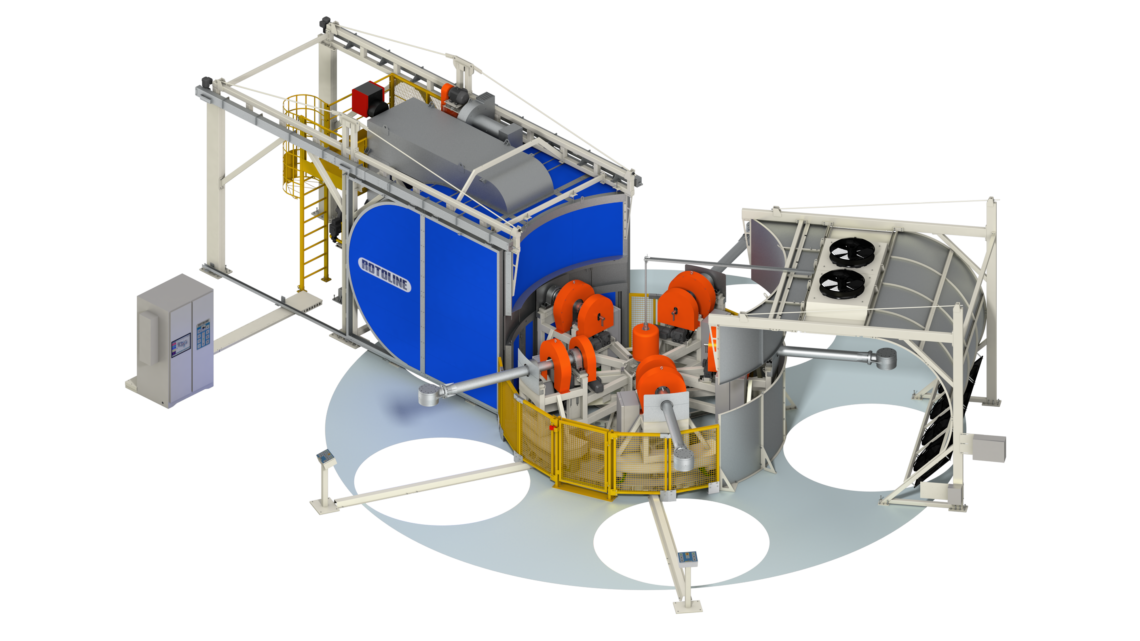

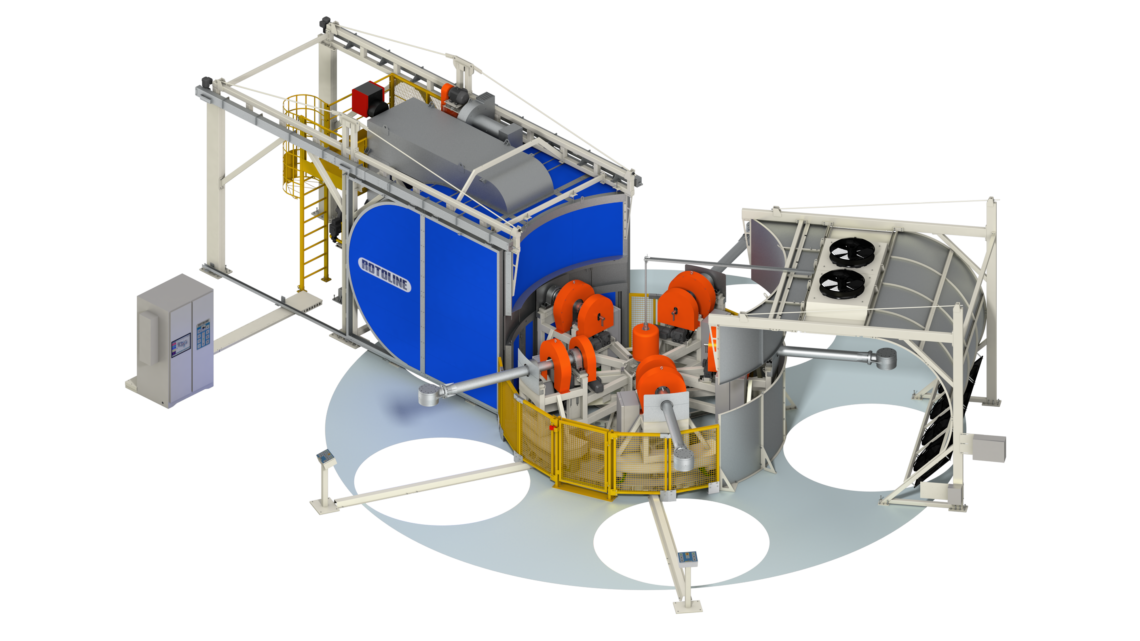

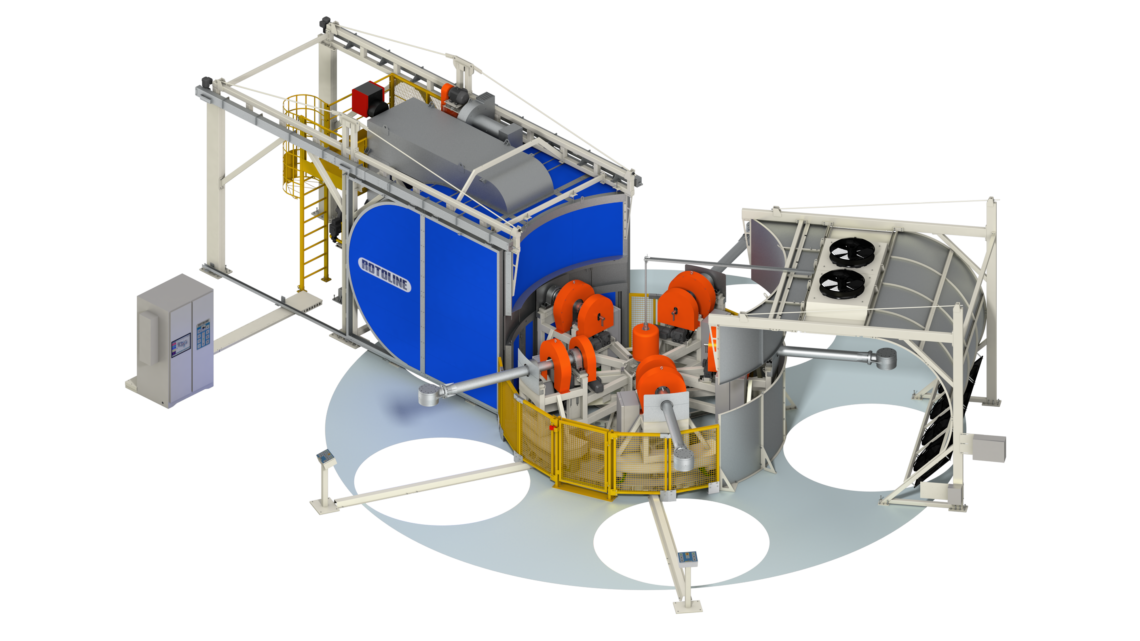

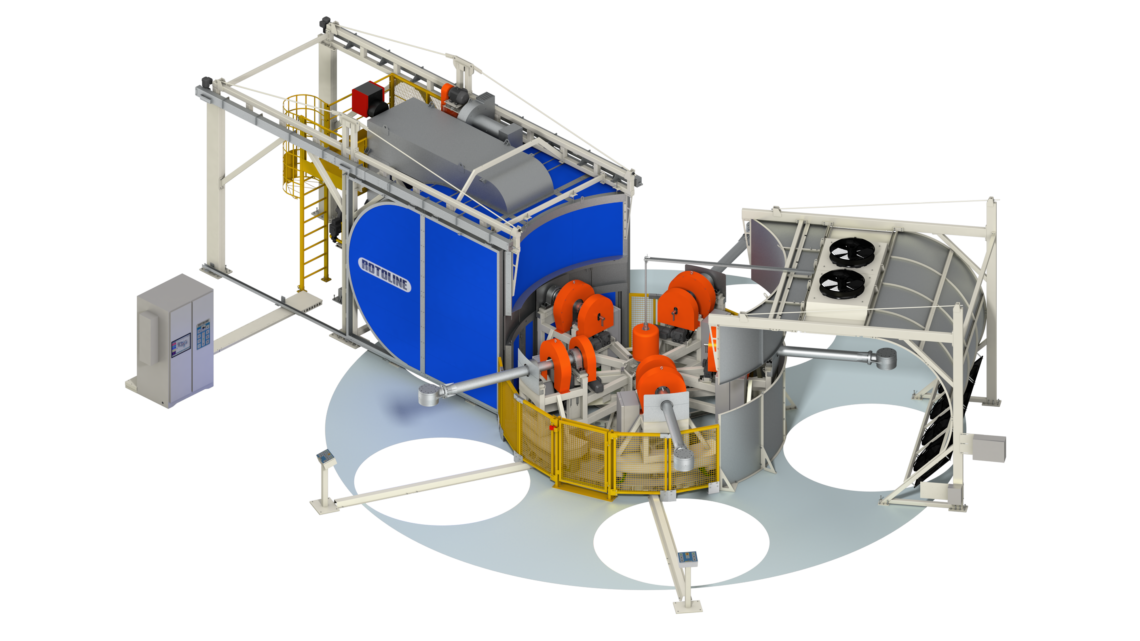

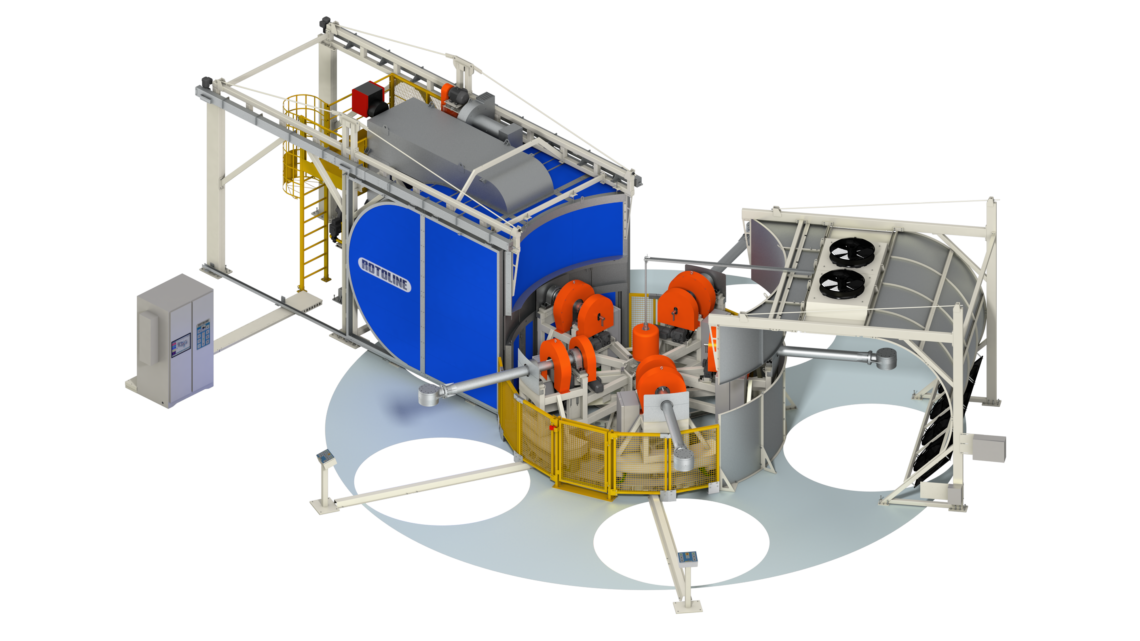

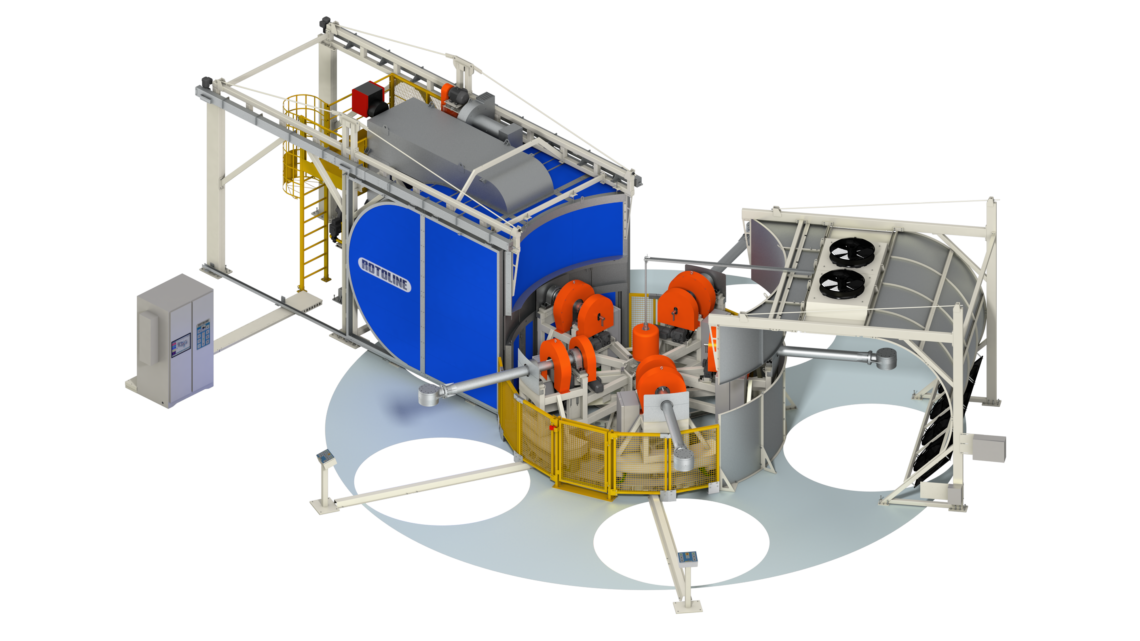

The Carrossel machine its so called because it has a central axis which the carts move through the different

stages of the production process. It is designed to work with three or four independent carts, and the machine was developed for the manufacturing many different products in polyethylene.

Ideal for sequential parts production in large quantities, it offers up to 20% more productivity when compared to other machines. With five independent stations, the oven; pre-cooling; cooling; loading / unloading and stand by steps, can be made individually, reducing machine downtime, as each arm can be in at a different station than the others.

With Carrossel machines, some accessories can be added, such as, the gas flow meter. It works integrated with the machine's control software, providing gas consumption records by cycle, by number of parts produced and by weight of material processed.

Another option is the Rotoline Wireless Temperature Control system, RWTC. This system finds a standard system behavior, which results in an ideal oven temperature, where the part is formed with quality and repeatability. This system uses self adjustment oven time control by temperature instead of using the programmed oven time, this avoids the influence of eventual external temperature differences, such as ambient temperature, and minimizes the gas consumption to the less as possible for parts manufacturing.

The Carrossel machine is offered in many different sizes as shown below:

MACHINE

DIMENSIONS

CR 2.60

HA

3900 mm

153,5 in

CA

13600 mm

535 in

PA

9440 mm

372 in

Ø OVEN

2700 mm

106 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

CR 3.10

HA

4530 mm

178 in

CA

16500 mm

649,6 in

PA

11115 mm

438 in

Ø OVEN

3200 mm

126 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

CR 3.60

HA

5450 mm

214 in

CA

19790 mm

779 in

PA

13150 mm

517 in

Ø OVEN

3700 mm

146 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

CR 4.10

HA

6000 mm

236,2 in

CA

22860 mm

900 in

PA

15370 mm

605 in

Ø OVEN

4200 mm

165,3 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

CR 4.60

HA

6670 mm

263 in

CA

24960 mm

983 in

PA

16600 mm

653 in

Ø OVEN

4700 mm

185 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

CR 5.20

HA

7542 mm

297 in

CA

28208 mm

1110 in

PA

18748 mm

738 in

Ø OVEN

5300 mm

208 in

* Measurements are approximate and may be adjusted by the manufacturer.

DIMENSIONS

OF THE MACHINE

CR 5.20ES

HA

7857 mm

309 in

CA

29536 mm

1163 in

PA

19553 mm

770 in

Ø OVEN

5900 mm

232,2 in

* Measurements are approximate and may be adjusted by the manufacturer.

The equipment is designed with a high capacity air recirculation system (equipped with start and speed control by variable frequency drive) and heating system with high efficiency for every cycle. The carts can be equipped with “Central” arm (STRAIGHT) or optional Offset arms ("C" or "L"). Gearmotors and variable frequency drives allows axis speed adjustment in any rotation direction.

See below a small sample of the variety of products that can be manufactured by the rotational molding process.

A rotomoldagem de plástico é uma das técnicas mais importantes para o desenvolvimento de produtos neste material. Se você está procurando um guia prático para entender e obter os melhores resultados

Escolher a máquina de rotomoldagem certa para o seu negócio é um processo bastante complexo e requer diversas pesquisas e entendimento no assunto. Amplamente utilizada pelo setor industrial, o plástico rotomoldado

A Rotoline é responsável pela fabricação e assistência técnica de máquinas de rotomoldagem inovadoras e revolucionárias para o mercado plástico. A empresa, que está no mercado mundial há mais de 20

Alguns cuidados básicos e de rápida execução se mostram de extrema importância na contenção, detecção e solução de problemas no uso de máquinas rotomoldadoras. Até porque o custo da manutenção programada

Rotoline is a global supplier of Rotational Molding Machines with one of the highest quality standards. Currently, it has machines installed on 5 continents.

MACHINES

ROTOLINE BRASIL

ROTOLINE USA

ROTOLINE EUROPE

The Cooling System is composed by fans with high performance propellers with large flow rate and low noise levels.

They are equipped with spray nozzles ring system programmable in the recipe, the "Air Assist" uses water + compressed air.

Ideal para a produção sequencial de peças em grandes quantidades, apresenta mais produtividade em relação a outras máquinas.