The Shuttle rotational molding machine series work with a central oven, two stations and two carts with straight or offset arms. Composed by two cooling stations, it offers a special ratio of productivity/economy, as well as, advantages of easy mold changing and the option of working with one or two stations.

It is indicated for manufacturing different products, and allows the use of different molds at the same time, producing with different times and recipes on each cicle. With Shuttle machines, some accessories can be added, such as, the gas flow meter. It works integrated with the machine's control software, providing gas consumption records by cycle, by number of parts produced and by weight of material processed.

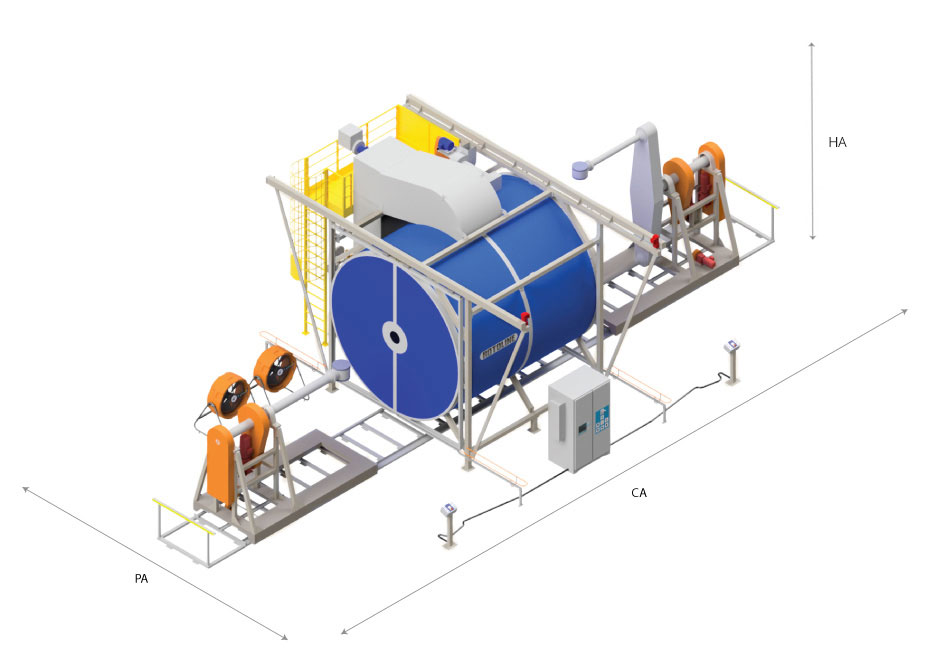

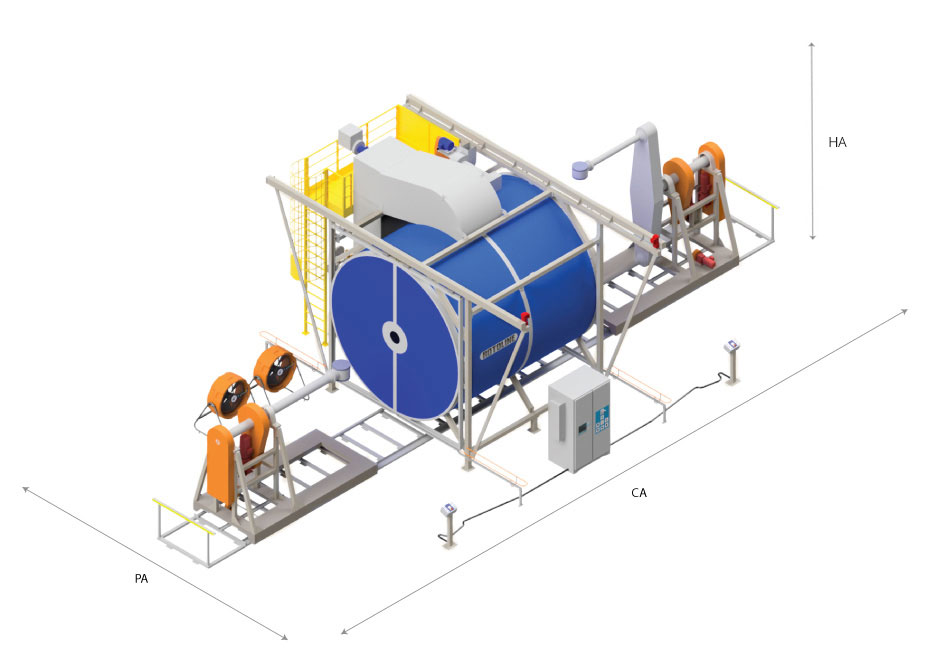

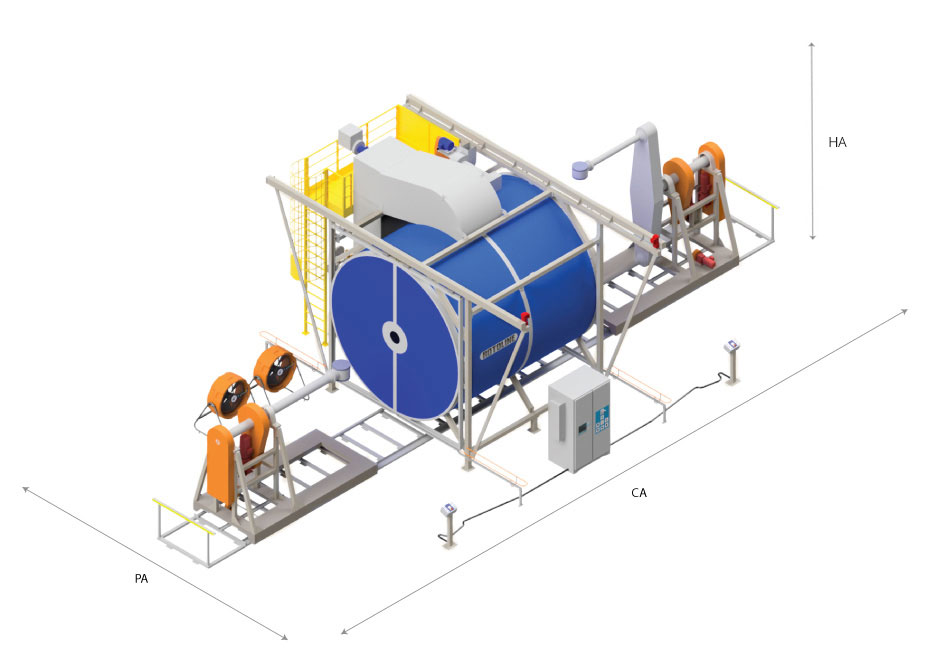

MACHINE

DIMENSIONS

DC 1.50 XT

HA

2760 mm

109 in

CA

8000 mm

315 in

PA

3880 mm

153 in

Ø OVEN

1500 mm

59 in

* Measurements are approximate and may be adjusted by the manufacturer.

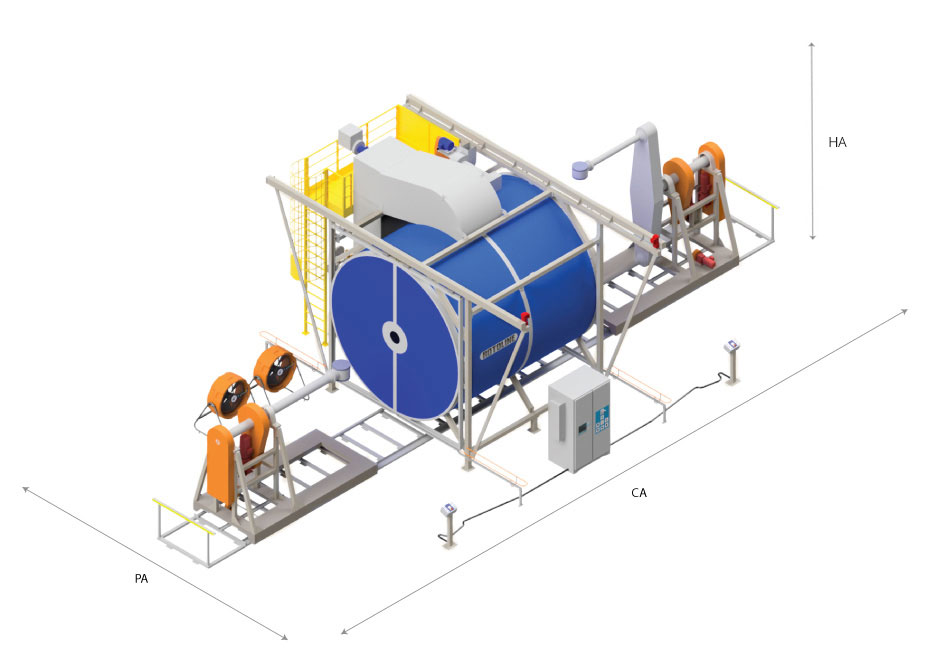

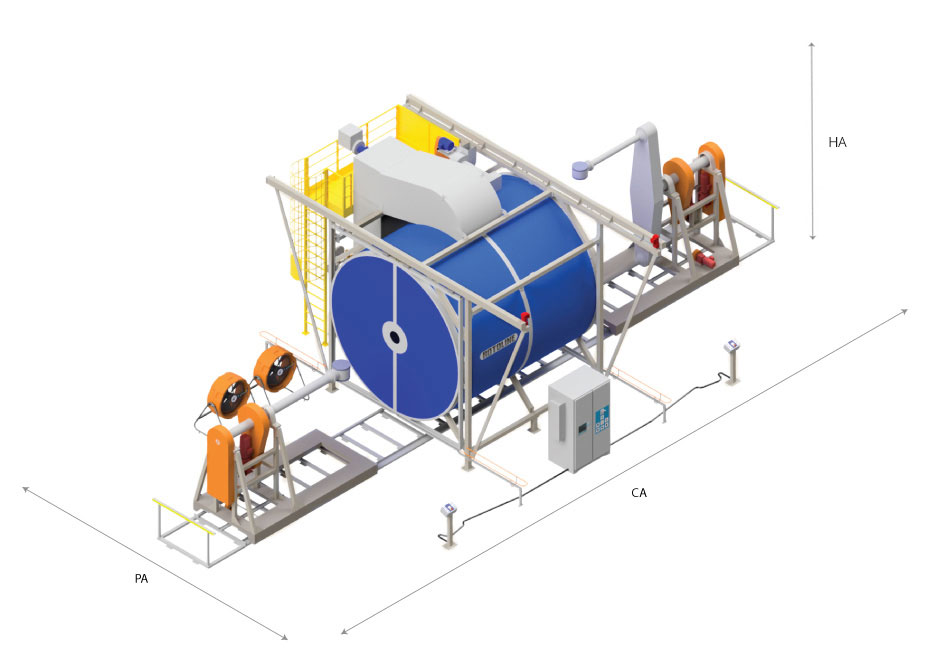

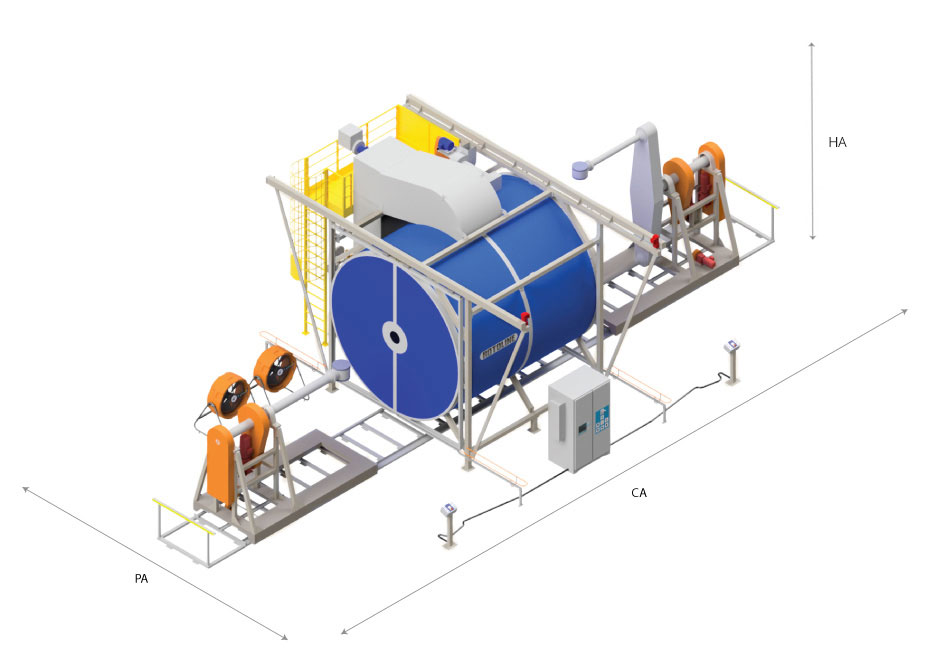

MACHINE

DIMENSIONS

DC 2.50 XT

HA

3710 mm

146 in

CA

12800 mm

504 in

PA

7060 mm

278 in

Ø OVEN

2500 mm

98 in

* Measurements are approximate and may be adjusted by the manufacturer.

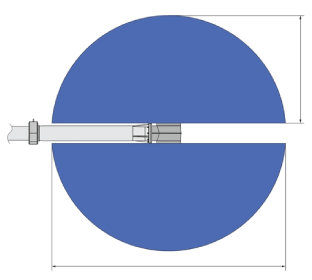

STRAIGHT ARM G3

LOAD CAPACITY

1400 Kg / 3100 Lb (US)

1094 mm

43 in

2380 mm

94 in

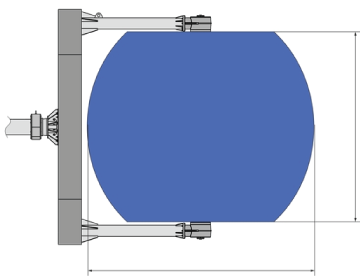

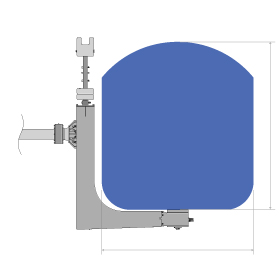

OFFSET ARM "C" G3

LOAD CAPACITY

800 Kg / 1800 Lb (US)

1830 mm

72 in

2375 mm

93 in

BRAÇO OFFSET “L” G3

LOAD CAPACITY

1000 Kg /2200 Lb (US)

2050 mm

81 in

1950 mm

77 in

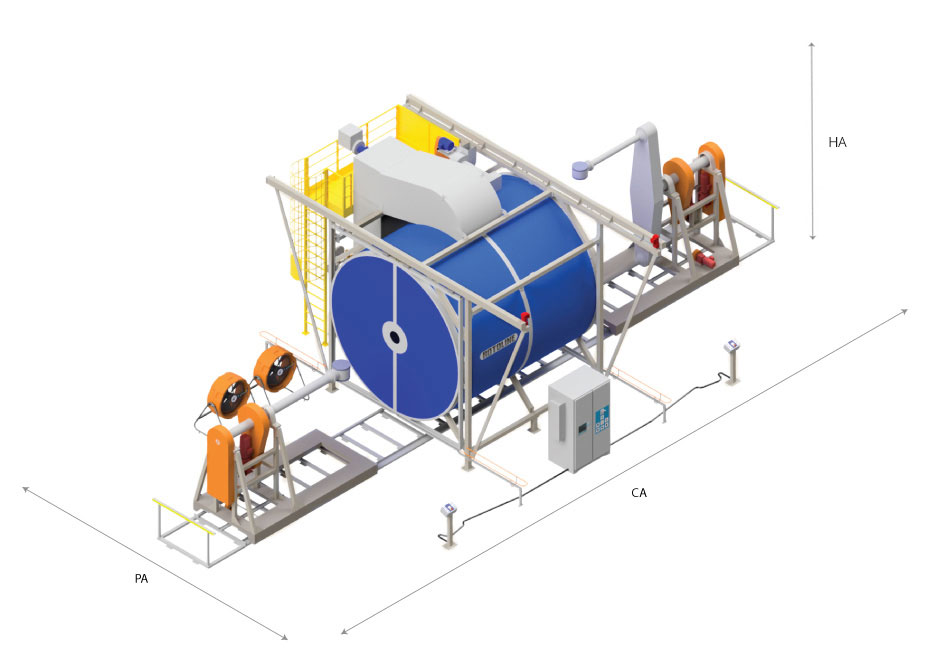

MACHINE

DIMENSIONS

DC 3.00 XT

HA

4725 mm

186 in

CA

14800 mm

583 in

PA

7240 mm

285 in

Ø OVEN

3000 mm

118 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

DC 3.50 XT

HA

5080 mm

200 in

CA

16000 mm

630 in

PA

7940 mm

313 in

Ø OVEN

3500 mm

138 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

DC 4.00 XT

HA

5500 mm

217 in

CA

18400 mm

725 in

PA

8650 mm

341 in

Ø OVEN

4000 mm

157 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

DC 4.50 XT

HA

6440 mm

254 in

CA

22450 mm

885 in

PA

9820 mm

387 in

Ø OVEN

4500 mm

177 in

* Measurements are approximate and may be adjusted by the manufacturer.

MACHINE

DIMENSIONS

DC 5.00 XT

HA

6500 mm

256 in

CA

24530 mm

966 in

PA

11150 mm

439 in

Ø OVEN

5000 mm

197 in

* Measurements are approximate and may be adjusted by the manufacturer.

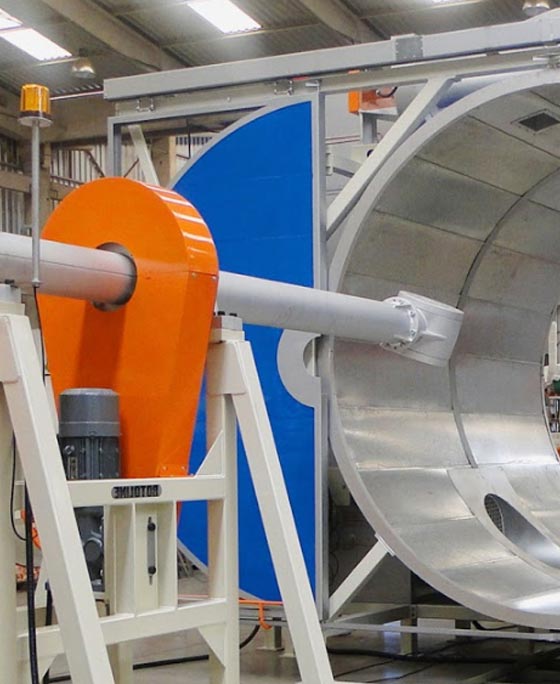

Composed by three support bases (chassis), one for each station (cart) and the third for the central oven, which has an exclusive horizontal cylindrical shape, with a diameter up to 5 meters. Made of treated carbon steel, it is equipped with a recirculation fan with start and speed control by variable frequency drive, recirculation duct and burner. Both carts have a “Central” arm (STRAIGHT) or a “C” type arm (OFFSET) option. Each has three gearmotors, in addition to a double cooling system and variable frequency drives.

The machine is equipped with a Main Panel where all electromechanical and programmable components are installed and connected. It also has two individual control podiums for each station, giving the operator three control and operation places. All panel connections to the field devices are made using quick plugs (plug and play), reducing the time needed for installation. It also has a complete electrical design, easy to interpret, enabling quick checks and agility in maintenance.

The machine's Programmable Logic Controller (PLC) is loaded with a software management control system which gathers information from multiple sensors such as temperature and pressure, installed in various parts of machine, doing all the interlock and control functions of machine operation and providing a specific an concise input to controller of the gas burner.

See below a small sample of the variety of products that can be manufactured by the rotational molding process.

Rotoline is a global supplier of Rotational Molding Machines with one of the highest quality standards. Currently, it has machines installed on 5 continents.

MACHINES

ROTOLINE BRASIL

ROTOLINE USA

ROTOLINE EUROPE

The Shuttle machine has 2 carts that can be equipped with a straight arm or an "C" offset arm, both build with a reinforced structure, heat treated to release the steel stress.

The cooling, load and unload stations allows the Shuttle machine to work simultaneously in two stations at the same time, with different recipes and molds.